Consulting Solutions

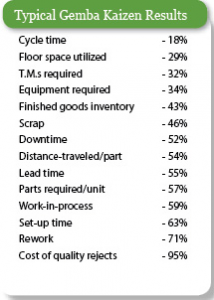

During these challenging economic times, Companies need more than ever to think and plan strategically, exercise “cost-cutting” and “process streamlining”, and make overall improvements to the operations and the bottom-line. GKI’s knowledgeable experts collaborate as the trusted advisors with the executives of each organization to create an environment in which the Team Members learn to continuously, and incrementally improve the processes. (Kaizen philosophy).

Our expert consultants lead your teams to implement Kaizen projects which are developed based on the “3S system”. The solutions which are proposed and implemented will result in the following benefits to the organization:

To find out more, please fill out this form

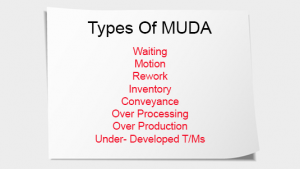

We will provide your team with the right set of "glasses" to see and identify inefficiencies, bottlenecks, and different types of waste (Muda) in your processes and system.

In the 1st step of 3S system, we will do an assessment of the existing current condition.

We will:

We will assist your team to Kaizen the existing status, do root-cause analysis, and implement "Solutions".

In the 2nd step of 3S system, we will implement simple, quick, inexpensive solutions.

We Will:

We will develop a sustainable and lasting result, preventing recurrence of the problems through conducting supervised follow-up with your team.

In the 3rd and final step of 3S system, we will coordinate a monitoring system to assure sustainability of implemented solutions and achieved results.

We will:

- See

-

We will provide your team with the right set of "glasses" to see and identify inefficiencies, bottlenecks, and different types of waste (Muda) in your processes and system.

In the 1st step of 3S system, we will do an assessment of the existing current condition.

We will:

- Solve

-

We will assist your team to Kaizen the existing status, do root-cause analysis, and implement "Solutions".

In the 2nd step of 3S system, we will implement simple, quick, inexpensive solutions.

We Will:

- Sustain

-

We will develop a sustainable and lasting result, preventing recurrence of the problems through conducting supervised follow-up with your team.

In the 3rd and final step of 3S system, we will coordinate a monitoring system to assure sustainability of implemented solutions and achieved results.

We will:

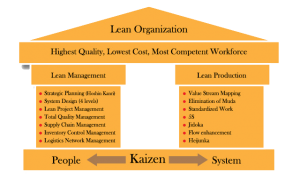

Lean Management

Lean Production